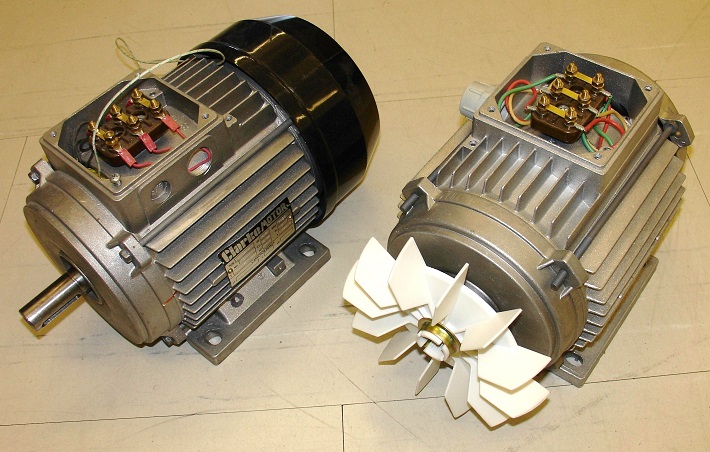

Electricity is one of the driving forces of today’s economy and everyday life. However, electricity wouldn’t have been as impactful as it is without electric motors. Even small electric motors have come a long way, and they’re capable of providing a lot of power. All it takes to get power from them is flick a switch. An electric motor is an electro-mechanical machine that can convert electrical energy into mechanical energy. Any device that can effectively produce rotational force with the help of electricity can be considered an electric motor.

An electric motor works thanks to electromagnetism. When an electric current is sent along a wire, it creates this field around it. With the wire near a magnet, the field interacts with the field of the magnet causing both the magnet and wire to attract or repel each other. This creates movement that results in mechanical energy. Electric motors can power everything from big machines to small RC cars and more exciting tech such as e-bikes.

Can an Electric Motor Generate Electricity?

While an electric motor uses electricity to create movement, unfortunately, it cannot generate electricity. Electricity needs to be sent to either a big or a small electric motor in order for it to work. Instead, electricity can be created with the help of a power generator.

DC Electric Motors

The first type of electric motor to ever be created was a DC motor. These small electric motors are easy to install and provide a linear speed-torque curve since they operate on DC (direct current). Electric DC motors are able to provide quick starting, stopping, acceleration, reversing, as well as high starting torque. This is why they can be found powering small appliances and tools that don’t need a lot of continuous power but need a surge burst. DC motors can be supplied by varying voltage, and they’re available in a wide range of voltages with the most common ones being 12V and 24V.

Brushed DC Motors

This is a type of DC motor used in RC cars that uses small brushes to make the magnet inside the motor turn and thus, generate motion. This is the more traditional variant of DC motors which are also available in four different versions. These include shunt wound, series wound, compound wound and permanent magnet brushed DC motors.

Brushless DC Motors

The more capable DC motors have no brushes in them. Instead, they use sensors to detect the position of the rotor in the motor and move it using a controller. This makes brushless DC motors perform better and they have a longer lifespan. Brushless DC motors require less maintenance, but one downside is that they are more expensive than their more conventional brushed counterparts. The efficiency of brushless motors ranges from 85 to 90% which is why they are used in places where ruggedness and reliability are important. They are often used with pumps, compressors and fans.

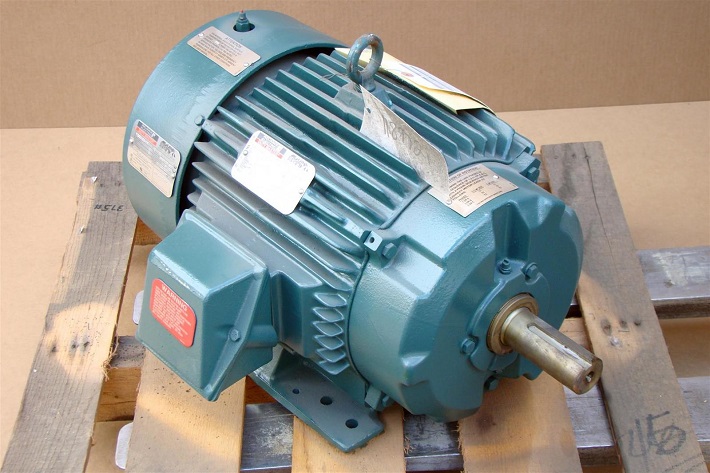

AC Electric Motors

What most appliances and devices rely on today is AC (alternating current). Motors that rely on AC are far more flexible than those that rely on DC. One of the more notable features of AC motors is their VSD (variable speed drive). This gives AC motors an adjustable torque limit and operational speed, as well as controlled acceleration, reduced power line disturbances and controlled starting current.

As of lately, the purpose of VSD has been adding extra features and some PLC (programmable logic control) functions. While this makes AC motors more complicated when it comes to maintenance, it greatly increases their superiority over DC motors when it comes to the continuous output of mechanical energy.

Induction AC Motors

AC motors that run on what is known as asynchronous speed are known as induction motors. These electric motors use electromagnetic induction in order to convert electric energy to mechanical energy. They are called induction motors since the voltage in the rotor is induced, making them similar to brushless motors. Induction motors are the most commonly used AC motors since they rely on a single-phase which is known to be better for handling smaller loads that are common in household appliances.

Synchronous AC Motors

Instead of inducing the voltage in the rotor, a synchronous small electric motor tries to line the rotor with the rotating magnetic field. A synchronous AC electric motor has the rotor of a DC motor and the stator of an induction motor. This is because the working principle of a synchronous motor depends on a 3-phase supply. These types of small electric motors are mainly applicable in automation and robotics as they can provide stable speeds with no air gap between the rotor and the speed of the stator current. The speed of a synchronous motor remains constant even under varying loads which is why they are used in high-precision positioning devices.

What Size Electric Motor Do I Need?

The main thing to consider when picking the right size electric motor is to have a minimum of 900g thrust per 45kg weight. Application-specific factors also need to be considered, as they can alter the operation of the motor too.