A lathe is one of the most useful manufacturing industry machine tools. It is capable of cutting, sanding, drilling, facing, turning, and deforming workpieces. How lathes contain parts of work distinguishes them.

All lathes operate in the same manner: the component being worked on is secured on the lathe, and then it rotates against a fixed cutting instrument. However, lathes are typically classified as either “wood” or “metal.” But how do you know which one you need out of the two? That’s what we’re about to discuss in this blog post, so be sure to read up before your next project.

What Exactly are Wood Lathes?

The sturdy woodworking lathes are a specific form of lathes designed for woodworking applications. In other words, they are utilised for cutting, sanding, drilling, facing, turning, and deforming wooden workpieces. Mind you, they’re different from the wood carving tools. As with all other lathes, they operate by exposing a rotating workpiece to a stationary cutting implement. However, wood lathes are utilised exclusively for woodworking.

They are not appropriate for workpieces made from denser materials, such as metal. Wood lathes are more compact and straightforward than their metal counterparts. A fundamental pulley system controls the rotational speed of the workpieces. Although they generate less power than metal lathes, woodworking lathes are extremely effective at handling wooden workpieces, and creating items like lamp posts, furniture legs, baseball bats and ornaments in the example of bowls.

And What Is a Metal Lathe?

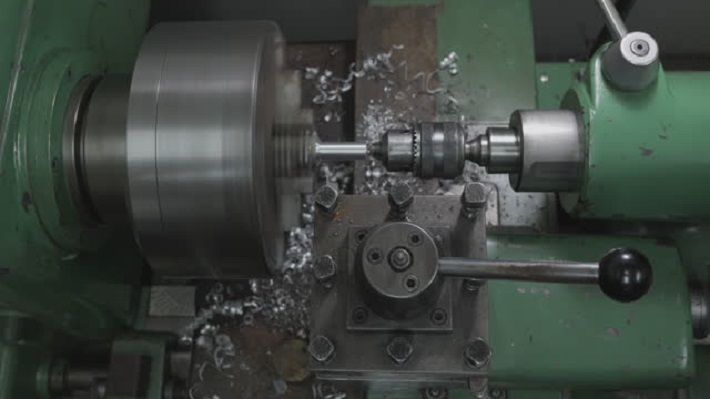

On the other hand, a metal lathe is a type of lathe that is capable of metalworking applications too. Metal lathes are extremely potent because metal workpieces are harder than timber workpieces. They can manipulate and deform steel, iron, aluminium, and other popular metals with force and precision.

Often referred to as a metalworking lathe, it is a robust machine used frequently in manufacturing processes involving metal workpieces. Metal lathes are utilised with a reinforced cutting implement mounted to a rotating mounting surface. The metal workpiece is placed on the lathe, and the cutting implement is then pressed against it.

Wooden workpieces can still be turned on metal lathes. Lathes made of wood support only wooden workpieces, whereas lathes made of metal support both wooden and metallic workpieces.

Applications

Beginning with the most apparent distinction, its applications. The wood lathe is utilised for timberwork, while the metal lathe is utilised for metalwork. Moving deeper into the specifics.

A wood lathe can be utilised for a wide variety of purposes. Sanding, deforming, turning, and piercing make you a skilled craftsman in this. However, these wood lathes have restricted power capabilities. Other than wood, metal and other rigid materials are prohibited here.

Alternatively, the metal lathe is the more adaptable. These tools can be used to carve both metal and timber wood. We might as well say, the sky is the limit here. A metal lathe enables the creation of industrial instruments or artistic creations from weighty metals such as steel or aluminium.

You can depend on its potent rotation, which can be anything. Keep in mind that due to the robust nature of metal lathes, many professionals are able to use them with wood as well.

Method of Use

This is another important distinction between a wood lathe and a metal lathe. Their functional metals differ like various coastlines. In the timber lathe, manual labour will be required. Even in the most advanced models, automation is scarce.

To operate with it, consistent direction is required. The metal lathe is primarily an automation component. Their labour involves multiple programming components. Here, you need not bother about pace or angle of turn.

Tips for Working Safely with a Lathe

Ordinarily, working with metal or wood parts entails minimal defensive measures and protective equipment due to their immobility. However, since the lathe rotates the object at high velocities, you must take additional precautions.

The most apparent threat is a fragment breaking off and hurtling towards you. Additionally, unfastened clothing, jewellery, and long hair may become entangled in the rotating machine. If you’re not cautious, this can cause significant injury.

Do not wear jewellery or loose garments, and draw back any long hair to prevent it from coming into proximity with the lathe. Additionally, it is advised that you don a face mask to safeguard your airways from the generated dust. Pieces of cedar wood can emit a toxic odour.

In Conclusion

I trust this brief guide has resolved many of your questions regarding the wood lathe and metal lathe. Now, the primary concern is whether a metal lathe should be considered for woodworking. If you work with both wood and metal, purchasing a metal lathe will save you an enormous amount of money.

Nonetheless, if you desire intricate craftsmanship in your tasks, you should opt for a wood lathe. For detail work, a wood lathe with a smaller diameter would be preferable.