The magnetic separator is a device that uses a magnetic field to remove metal (magnetic) compounds from a specific mixture, or to remove/separate minerals. The magnetic separator is very commonly used for processing heavy-mineral concentrates. There are different types of magnetic separators, each specifically designed for specific application. Generally, the magnetic separators are used for separating both ferromagnetic and paramagnetic particles. All magnetic separators come with specific size and specifications in order to provide the most efficient results.

The most common magnetic separators which can be found on the market are the following ones: weak magnetic separator, medium magnetic separator, and the strong magnetic separator. Depending on the material which is used, the magnetic separators can be divided into wet-type and dry-type magnetic separator, while depending on the magnetic field, there is constant, pulsating and alternating magnetic separator. The electro-magnetic separator has been extensively used in many industries for processing ferromagnetic minerals. Our suggested magnetic separator models are: belt type magnetic separator, single type magnetic separator and double type magnetic separator.

Belt Type Magnetic Separator – The belt type magnetic separator is widely used in many industries. The mixture of magnetic and non-magnetic materials passes through a strong magnetic field between two belts, one is magnetic and the other is a common conveyor. The magnetic belt gets the magnetic materials and discharges them from a specific chute. The gap between the magnet and the conveyor can be adjusted by the operator. For more efficient separation, the gap should be lower.

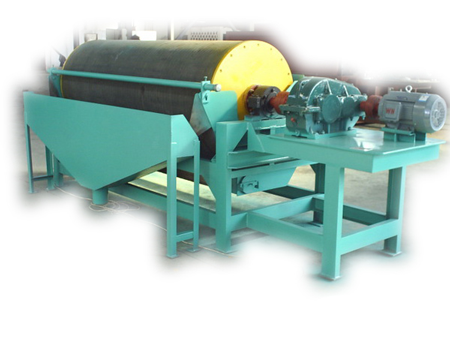

Single Drum Magnetic Separator – The single drum magnetic separator is used to separate iron from non-magnetic material. It is most commonly utilized in processing industries where it separates iron from chemicals, food, minerals, abrasives, ores, rock, glass, flour, cement, plastics, grain and other.

Double Drum Magnetic Separator – The double drum magnetic separator is ideal for products with high purity. It is similar to the single drum magnetic separator, but it includes an additional drum for better quality of the final product. It is most commonly used for separating iron from chemicals, minerals, refractory and other similar purposes. The double drum magnetic separator comes with vibrating material inlet (hopper) and a fully enclosed design for avoiding contamination.